We Prevent “Container Rain”

On – Grid or Off – Grid. Introducing the U.S. MULTI-PATENTED

Don’t just take our word for it

Scott M. with La Mesa-Spring Valley School District shares how these vents have changed the way they operate for 15 months and counting! Read More >>

John H. from Texas documents his 4 year experience with 360 Venting and how it resulted in a complete elimination of grain loss!

View Complete Test Results >>

John W. from Illinois expertly documents his 16 month field test with detailed product performance figures! View Complete Test Results >>

It really works! Check it out

Explore our site below to learn what truly sets us apart from conventional turbine and louvred venting options.

What makes us different?

What makes us your best choice for shipping container/conex venting solutions? We invented, manufacture, and market our own patented “flow through” technology to address the complex venting challenges of re-purposing a seagoing shipping container (conex) into a reliable storage facility.

How does it work?

The DRY-CON X® Ventilation System consists of an Exhaust and Intake. Our multi-patented Exhaust Vent design creates a “Venturi Effect” when air passes over or through the vent . The vacuum this creates pulls stale, moist air out of the enclosure and then fresh, ambient air is pulled through the Intake Vent completing the multiple, daily air exchanges necessary to prevent moisture buildup and mitigate excessive heat.

Continue exploring our website to learn how we can give you the best protection available regardless of your climate conditions.

Yes, it really works. Here’s proof—

We already know that traditional louvered venting can not create the “drive” necessary for continuous air exchanges and is not an effective solution when you need constant airflow. It’s an engineering fact. Our multi-patented technology now makes that possible. Explore for yourself!

Texas Grain Storage – 4 Year Test Results

Illinois Heat Mitigation & Moisture Control

Must See Videos

Easiest Ever Installation

Wind Tunnel Performance Test Results with Turbine and Louvred Types

How Tough is Our Polycarbonate Construction?

Click here for an INCREDIBLE demonstration.

Vent Placement

Determining Vent Placements For My Personal Container Location:

How Many Do I Need and Where Do I Put Them ?

The goal of the DRY- CON X ® system is to utilize outside air currents with a combination of Intake and Exhaust Vents to create a “flow through”situation inside the container that exhausts old ,stale,moisture laden air and replaces it with fresher,ambient outside air. This is the key to moisture prevention.

How Many Do I Need ?

For a 20 foot container we recommend 1 Intake Vent and 1 Exhaust Vent. For a 40 foot container and high cube we recommend 2 Intake Vents and 2 Exhaust Vents.

Where Do I Put Them ?

Proper placement of our system in your individual location will ensure maximum performance. Primary variables to consider include the container size,the direction the doors face, the direction the wind is COMING FROM and common existing wind patterns and speeds at your location. (No concern about gusty or chaotic wind as they actually enhance the performance of the DRY-CON X® system.)

Click below for an instant vent placement guide and customized Kit !

Please Note

Keeping a large metal box condensation free without power is not always simple as some locations are tougher than others. For the best performance with our product, download our free guide, “8 Steps to a Dry Container,” and implement whatever is possible.

We want success for all our customers, so please review the link listed above to ensure all the variables have been considered when designing your ventilation system and we welcome your call if you have questions.

Installation

360 Products sets the standard for easy installation – No tools required after hole cutting

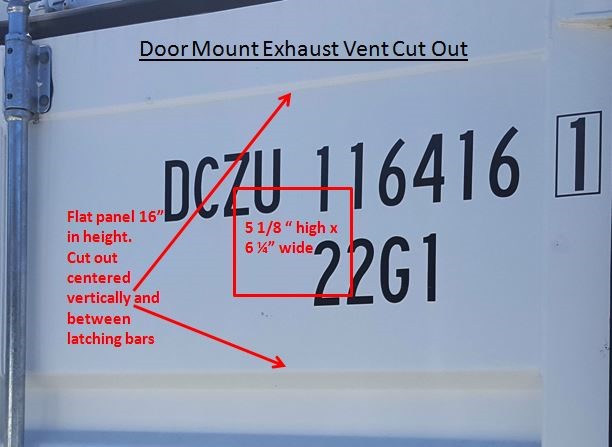

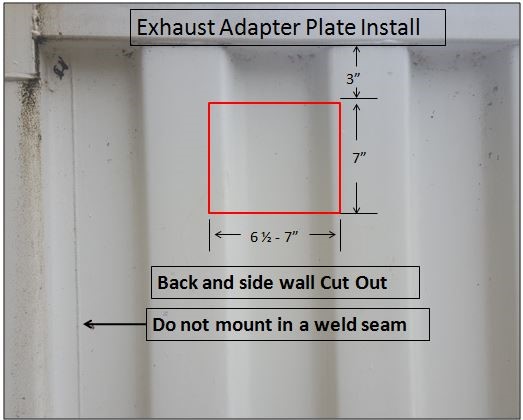

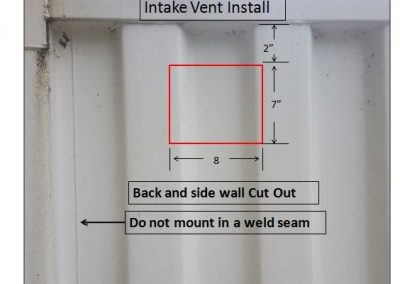

Once the vent locations are determined, mark the port openings as per the cut-out instructions for both the Exhaust and the Intake. For step-by-step walkthrough, read the full details below.

Installation

- Once the vent locations are determined, mark the port openings as per the cut-out instructions for both the Exhaust and the Intake, as below.

2. Cut the rectangle holes, clean off filings

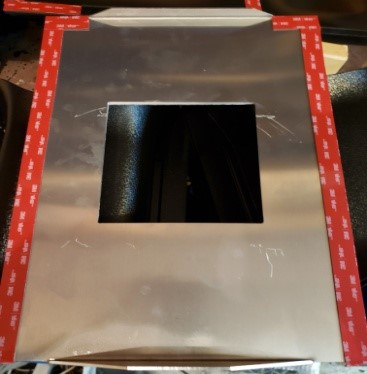

3. Prep the mounting surfaces with the abrasive sanding block now provided. Clean thoroughly and apply rubbing alcohol (IPA) diluted by 50% water. Dry with a clean rag.

5. Press well for about a minute to make sure initial contact is made. Cure is secure at 40% (after 20 minutes). The “Exhaust Driver” has two parts, port then cover. Intake has one part. The 3M® tape takes about 24 hours to cure completely.

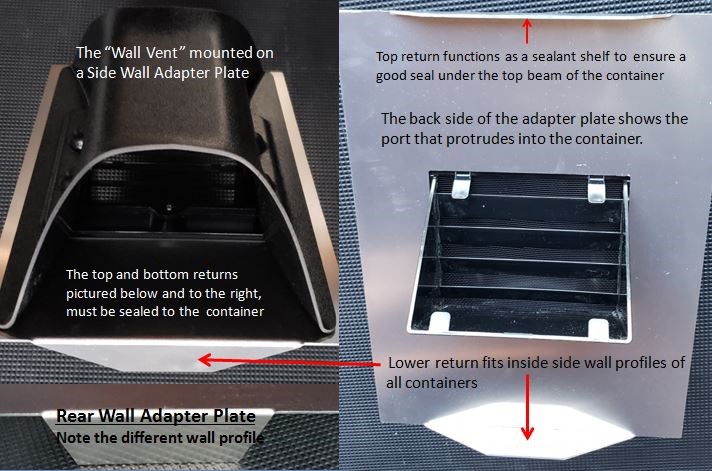

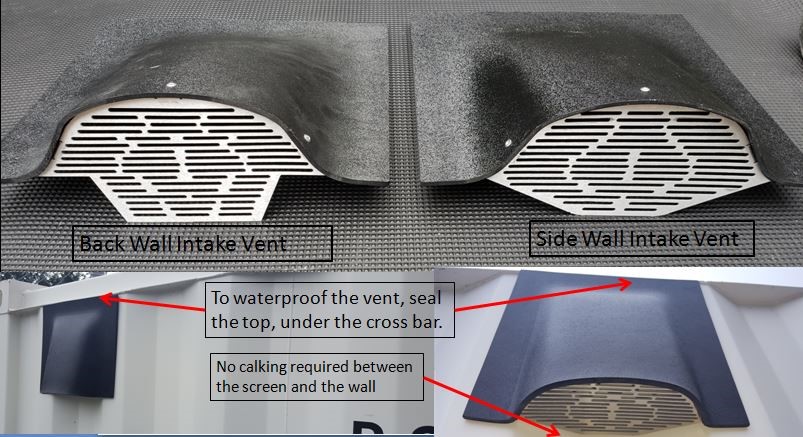

6. The 3M® brand commercial grade tape has outstanding adhesion properties and provides an excellent weather seal. To compensate for container imperfections, an exterior sealant is still required for the top of the intake and the top and bottom of the adapter plates (if required). For the extra minute it takes, we suggest applying a bead of sealant around the outer edges of all the vents and parts.

You are done…Simple as that!

Note: There are literally hundreds of sealants in small, individual tubes available at all Hardware/Home Improvement stores across the country. We recommend asking their sales associates which ones they would recommend for a small, one time application such as ours.

Testimonials

FOUR SEASONS TEST RESULTS

“Bob,

I just wanted to let you know that the vent system I bought from you back in November 2021 has been working out great in my 20 foot container. I wanted to take it through “all the seasons” here in central Virginia where we have moderate temperatures in the winter and very high humidity in the summer before I sent a review. No condensation or fumes inside whatsoever! Very satisfied.”

Grain Storage in Texas!

“I can’t explain what a difference your product has made for my container. On a day like yesterday with high heat and humidity the inside of that container would normally be unbearable. Thousands of pounds of feed, a sealed container, high heat and humidity created toxic fumes that were overwhelming. Your venting system has corrected these issues and now my container is comfortable to enter even on these extreme days.

Thank you for a great product!”

Click Here for the Article on John’s Year-long Ongoing Field Testing.

Note from 360 Products: John has reported to us that he has zero grain loss now since installing the vent system over 1 year ago. This was beyond even our expectations in a situation this complex.

Hi Bob,

We installed the 2 sets of vents on my 40’ container 3 weeks ago. I’m happy to say, when you swing the doors open, there is little or no odor coming from the insecticide treated floors. I have begun to store items in it and feel confident the problem is solved. Thank you very much for speaking with me for nearly an hour and making me feel like the concerns with my container were important to you. That is very rare in these times. It was a pleasure doing business with you.

Goodbye Gas Fumes

“I recently reached out to the experts at 360 Products to help with ventilation of my 40′ shipping container used to house equipment for our construction business. Gasoline fumes were overwhelming before I installed their products. This system requires no electricity and totally solved our issue. Customer support is second to none. I highly recommend this company. Thanks for the fresh air!”

IMPRESSED WITH VENTS AND CUSTOMER SERVICE

“Wanted to let you know that I am impressed with your Vents. Also, really impressed that you answered your phone on 4th of July to help me. I realize that you did not have to do so and most would not have. Customer Service is extremely difficult to find anymore. I have told several friends about you. Thank you again for your help and expertise”

8/22/21 – 10 week follow up report

“Well good news! The ventilation system appears to be a success so far! Last two trips up to the property has shown no signs of moisture. Thanks for the great product!”

U.S. NAVY

“I have no problem with you sharing our feedback, especially to fellow Naval personnel. [Y]ou’ll be pleased to hear that my supervisor had a chance to see the finished product after the install I did, and he is very pleased that not only the obvious functionality of the vent (feeling the breeze, he said), but also the aesthetic look the[y] add. We are definitely satisfied with your product and would recommend it to anyone in need of such a thing.”

6 Week Follow-Up

“The vents are doing a fantastic job and seems to be mitigating any form of moisture intrusion inside the Conex. All in all you have much to be proud about with this outstanding product and we would be happy to recommend it to anyone.”

I’M SHOCKED AT HOW WELL THIS HAS WORKED!

May 15, 2019

Yesterday when I started (installing the container vents) over half the container had “container rain.” Today the container ceiling is completely dry and the floor is much drier. And it rained overnight!

May 31, 2019 – UPDATE 2 WEEKS LATER!

Those vents have now been on the container for almost 2 weeks through record rainfall. The container is drier than it has ever been and the gear stored inside is beginning to not smell musty. I’m shocked at how well this has worked!

School District’s Mildew Problem Solved

“I installed your 360 container vent system back in Sept 2019. I am reviewing this product a year and five months later. I used two intakes and two exhaust per 40 foot container as suggested. We had a terrible problem with container rain and mildew build up. After we installed this system we cleaned all the mildew off the ceiling of four different containers and have not had a problem since. These vents work! Thanks Bob for your help in deciding to purchase this product.”

Note from 360 Products: Vent locations for toxic fume extraction are shown here in Sean’s installation pictures:

Contact Us

Veteran Owned & Operated

Hours

Monday-Saturday

9:00am-9:00pm EST

Distribution points

Linton, Indiana

Vancouver, BC

Address

P.O. Box 450

Linton, IN 47441

Note

A portion of your order total will be donated to charity and does not increase your product cost. This year's charities are: Saint Jude's Children's Hospital, Make-A-Wish Foundation, Salvation Army, Wounded Warriors project, and The Gary Sinese foundation (Veterans).